Please understand that green represents lower risk not no risk it should be noted that if sacrificial plating is incorporated in the fastener design then galvanic action can result in the deterioration of the sacrificial coating rather than of the fastener.

Steel sheets coated with tin reaction.

It is most often used to prevent rust but is also commonly applied to the ends of stranded wire used as electrical conductors to prevent oxidation which.

Tin is one of the basic chemical elements.

Tin plate is valued for its corrosion resistance solderability and weldability as well as for its attractive metallic luster.

X 36 the md building products 36 in.

Galvanic reaction chart below is a galvanic reaction chart for dissimilar metals.

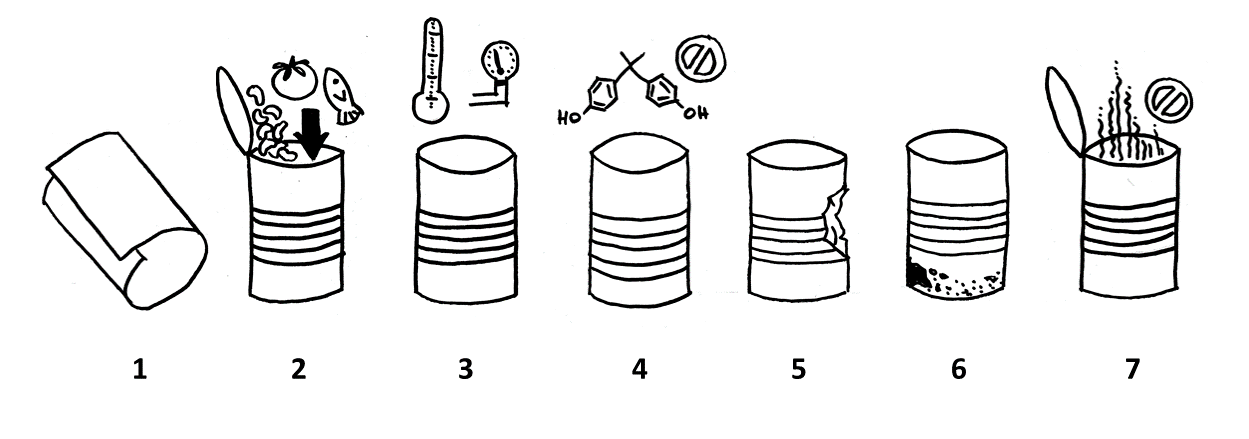

We re all familiar with tin cans that are used for holding many types of food and beverages.

However the entire coating is approximately 80 aluminium.

While tin plate has long been used by the packaging industry for cans and closures it is also commonly used in the production of deep drawn oil filter shells metal hose paint trays and more.

When refined it is a silvery white metal known for its resistance to corrosion and its ability to coat other metals.

The presence of two dissimilar metals in an assembly is not always a sign of trouble but it could be a problem.

Tin is also used in the production of pewter bronze and.

It is most commonly used as a plating on the steel sheets used to form cans for food containers.

Tin plate is produced from black plated steel that has been coated with tin on both sides by electrodeposition.

Mill aluminum union jack style perforated sheet metal offers a decorative way to complete your hvac door window hobby and cabinet projects.

It is easy to work with and very attractive in the home.

These containers are actually manufactured from sheet steel that is coated with a thin layer of tin known as tinplate.

These are called terne plate with the name tin terne sometimes applied to the higher tin coating.

Today roughly half of all tin produced is used in soldering applications.

The md building products 36 in.

Coating quality can be improved by electroplating the steel substrate with nickel before hot dipping in the terne bath.

Tinning is the process of thinly coating sheets of wrought iron or steel with tin and the resulting product is known as tinplate the term is also widely used for the different process of coating a metal with solder before soldering.

Steel sheets are commonly coated with alloys containing 7 10 or 25 tin.

Stainless steel and galvanized materials often are found together in the industry with applications such as galvanized fasteners stainless steel pressure vessels and roof and siding panels.