That due to the out of plane flexural stiffness of the sheeting the purlin s resistance to distortion and the localised deformations at the connection point.

Steel sheeting in plane stiffness resistance.

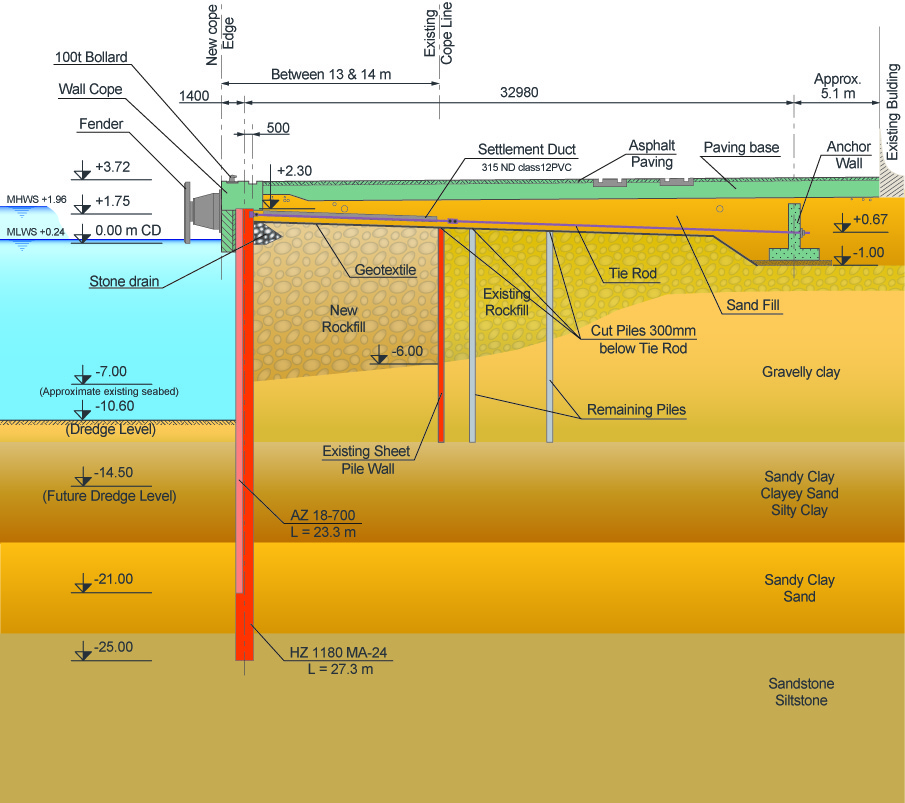

When the rankine state of failure has been reached active and passive failure zones will develop as shown in figure 1.

The coefficients in the empirical equations were derived from extensive test data in which assumptions were made to simplify the problem.

1 1 this test method covers determination of apparent in plane shear strength and stiffness properties of flat sandwich constructions with composite face sheets.

Pipe and support m p is the effective mass of the pipe including.

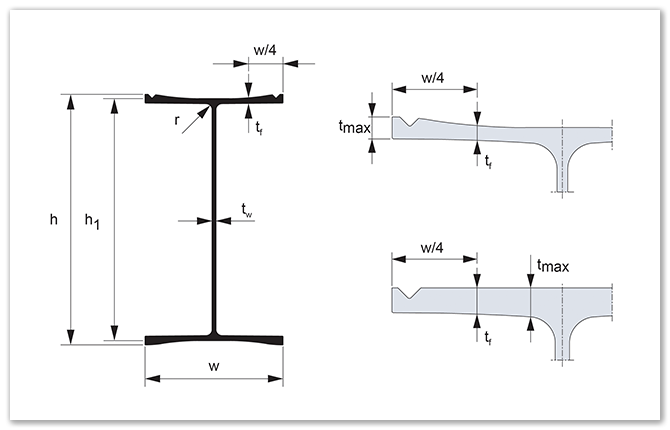

2 2 2 2 2 t z 2 w h 70 0 25h l π g eii l π s ei 1.

Some materials have a different young s modulus depending on the standard national annex.

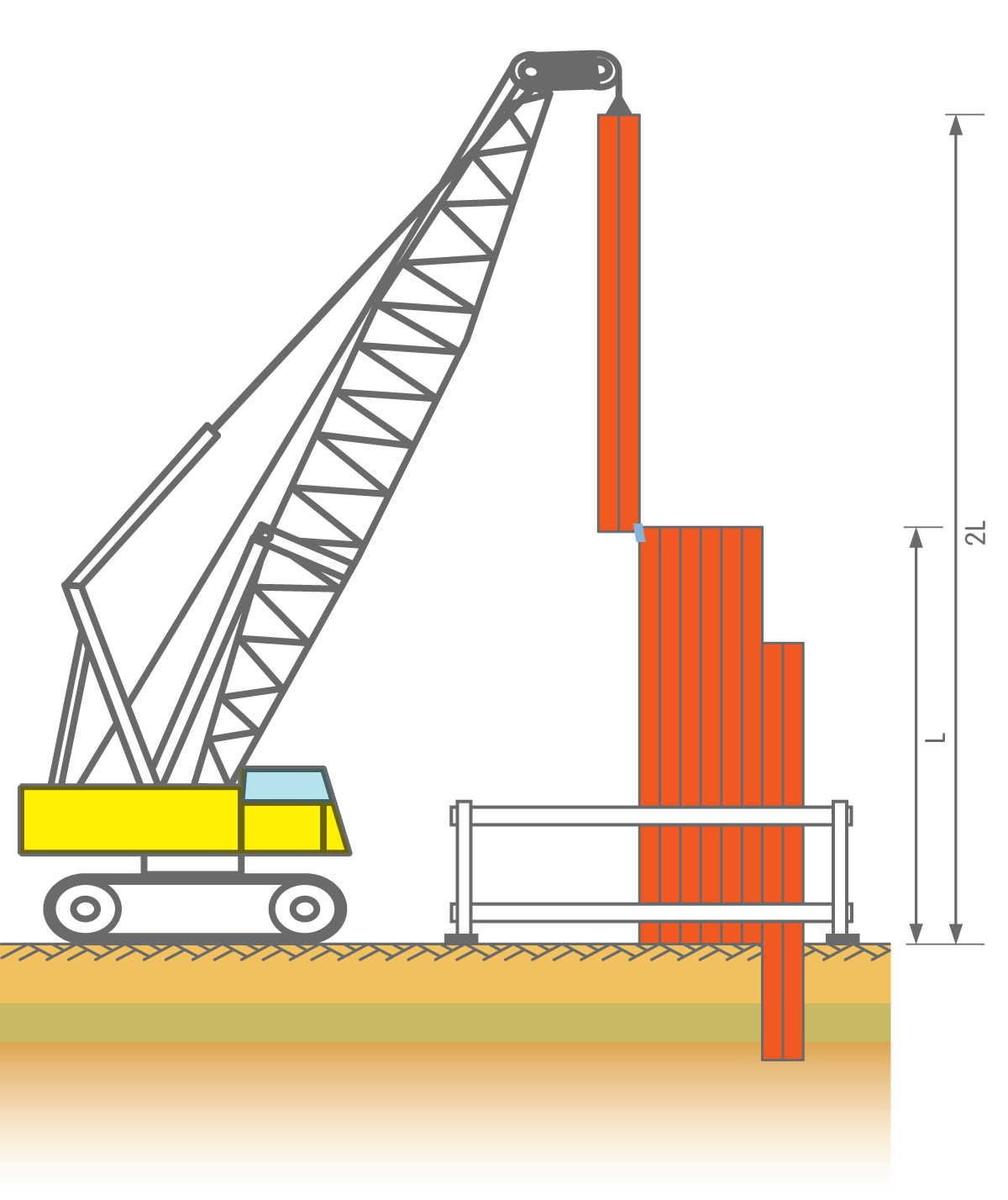

Steel sheet piling design manual.

Each groove bead or line will compound the strength and can also add a design to the panel.

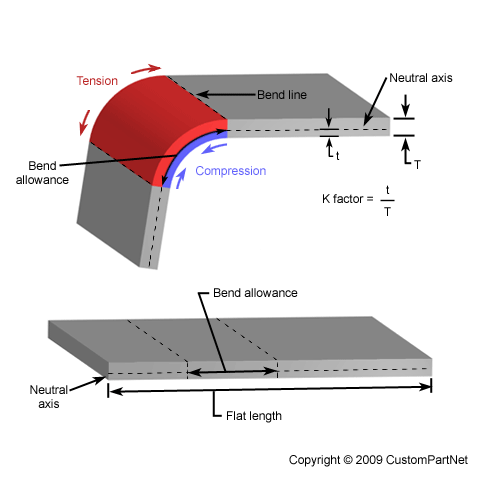

In design practice the current numerical model adopted in ec3 for determining rotational stiffness was first introduced by lindner and gregull who considered the stiffness into three parts.

Development of the plate bending element kirchhoff assumptions.

Pressing grooves ribs or designs into a piece of sheet metal will greatly increase the strength.

Trapezoidal sheeting cross section according to provision given in european standard 2 the beam might be considered as restraint in the plane of sheeting if equation 1 is fulfilled.

Sheet metal with structural grooved seams.

Once the stresses are known failure theories can be.

Membrane or in plane forces are neglected here and the plane stress resistance can be superimposed later that is the constant strain triangle behavior of chapter 6 can be superimposed with the basic plate bending element resistance.

Sheeting is steel of grade of s320 yielding stress fy 320 mpa.

Sloping surface and that a plane failure surface develops.

The stiffness matrix of an isotropic plate in diamonds gives the same results as calculated by hand.

Bending of plates or plate bending refers to the deflection of a plate perpendicular to the plane of the plate under the action of external forces and moments the amount of deflection can be determined by solving the differential equations of an appropriate plate theory the stresses in the plate can be calculated from these deflections.

Permissible core material forms include those with continuous bonding surfaces such as balsa wood and foams as well as those with discontinuous bonding surfaces such as honeycomb.

If you want to compare the stiffness matrix in diamonds to manual calculations make sure the correct standard here en 1992 1 1 is selected.

The stretched metal in those areas will hold tension in the panel and give it structural rigidity.

Coating and steel shell k c1 represents the coating stiffness k c2 denotes possible effect the coating has on the steel shell stiffness k s is the local shell stiffness of the steel pipeline.