The magnitude of m s was estimated to be 3 1 10 3 emu g for nc.

Standard sheet metal hysteresis curve.

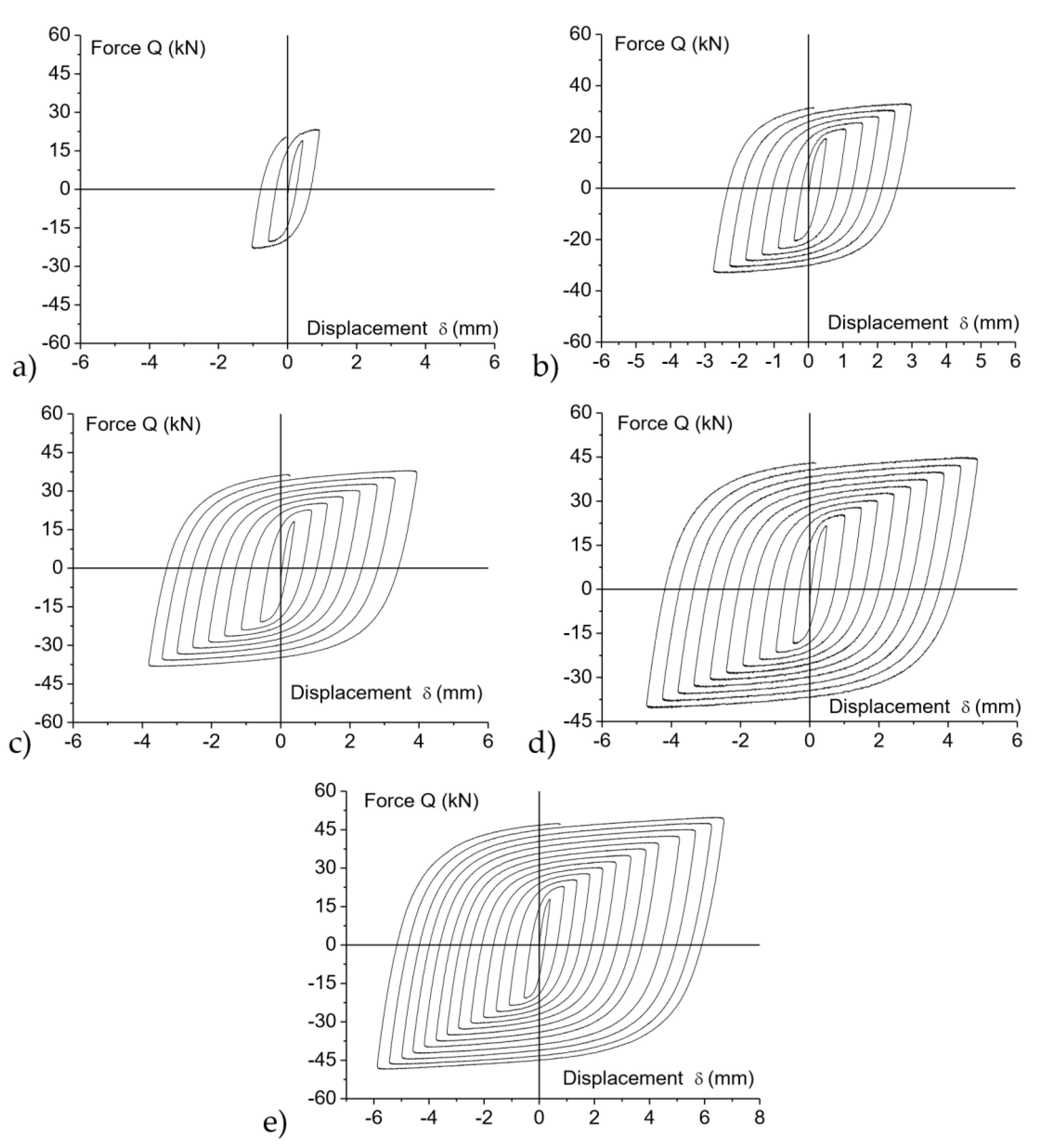

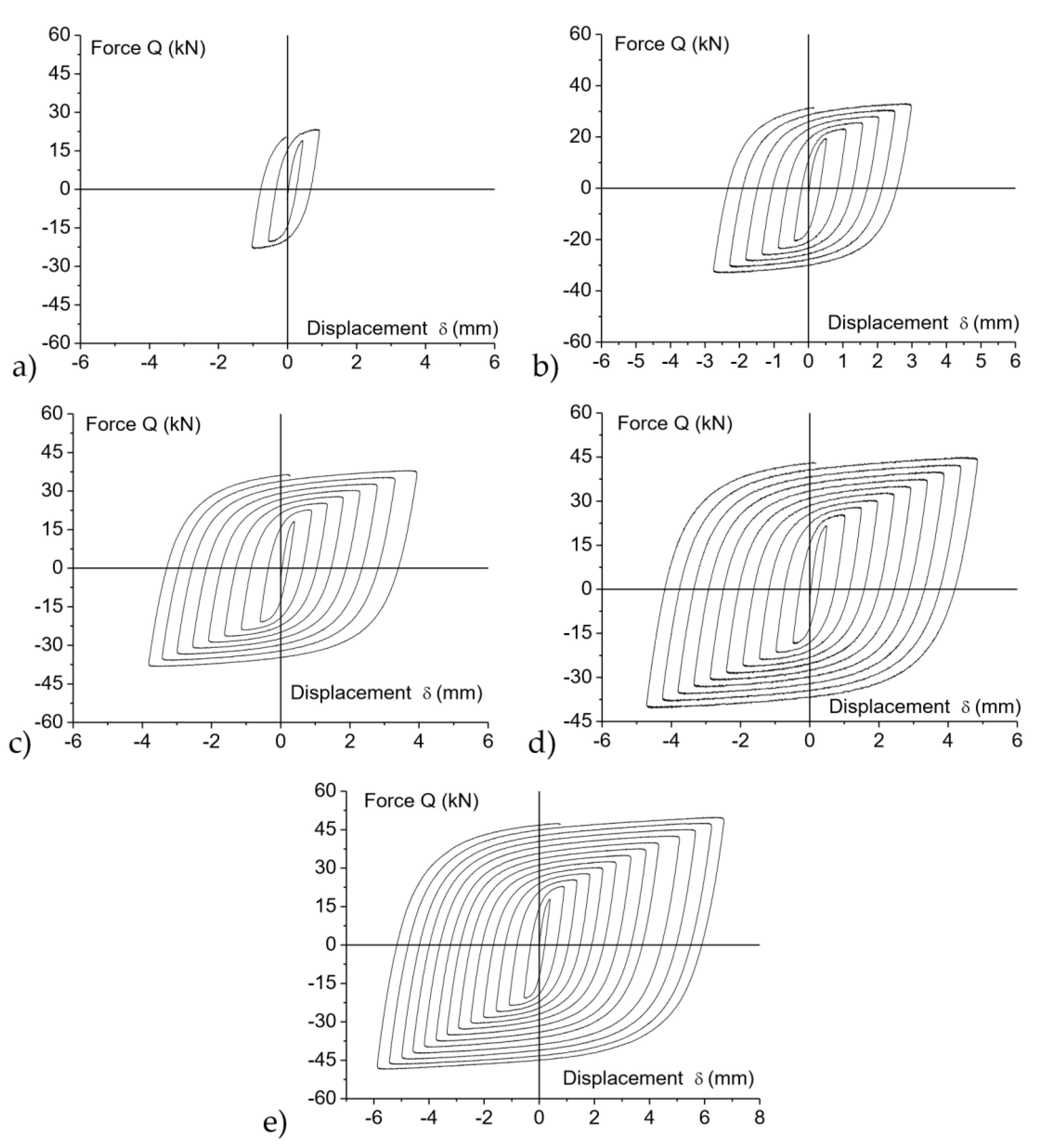

Hysteresis loops measured in tension related to the bauschinger effect were used to determine the relaxation behavior of a number of microalloyed and standard grade spring steels.

Journal of magnetism and magnetic materials 65 1987 71 75 north holland amsterdam low field magnetic hysteresis in iron cobalt nickel and steel g h j.

The curvature of the hysteresis is characteristic of the type of material being observed and can vary in size and shape i e.

The difference to the curve without the iron core can be shown by simply taking out the iron core and repeating the experiment.

Also known as press braking flanging die bending folding and edging this method is used to deform a material to an angular shape.

Several methods which deal with the problem of extended flow curve identification of sheet metal through a.

The hysteresis curve recorded for nc exhibits almost the least saturation behavior.

On increasing wt of co in nc the value of m s was increased.

The line connecting the tips of the curve places where the field sweep changes direction 1.

This is shown in figure 4.

This is done through the application of force on a workpiece.

Calcu late the hysteresis loss in watts when 1500 cm3 of the same material is subjected to an alternating flux density of 1 3 wb m2 peak value of a frequency of 65 hz.

The graph should now show a distinct curve which shows a hysteresis effect.

When using standard equipment and well known analytical formulas however the hardening behavior can only be identified up to the point of maximum uniform elongation.

1 the hysteresis loss and 2 eddy current loss.

The hysteresis loop of a sample of sheet steel subjected to a maximum flux density of 1 3 wb m2 has an area of 93 cm 2 the scales being 1 cm 0 1 wb m 2 and 1 cm 50 at m.

The normal curve can denote the b h dependence too.

The loop can be generated by using a hall effect sensor to measure the amount of magnetic field at various points when in the presence of a magnetic field when it is removed from the magnetic field and when a force is applied to bring the magnetic flux back to zero.

The force must exceed the material s yield strength to achieve a plastic deformation.

The enclosed area within the hysteresis shown in figure 2 1 is a measure of the energy lost in the core material during that cycle.

This loss is made up in two components.

The standard tensile test is still the most common material test to identify the hardening behavior of sheet metal.

The hysteresis loss is the energy loss when the magnetic material is going through a cycling state.

Wilson department of physics university college university of new south wales australian defence force academy campbell act 2600 australia received 15 august 1986 71 spheroidal.

Bending is one of the most common sheet metal fabrication operations.

Figure 3 shows an example of what can be expected.