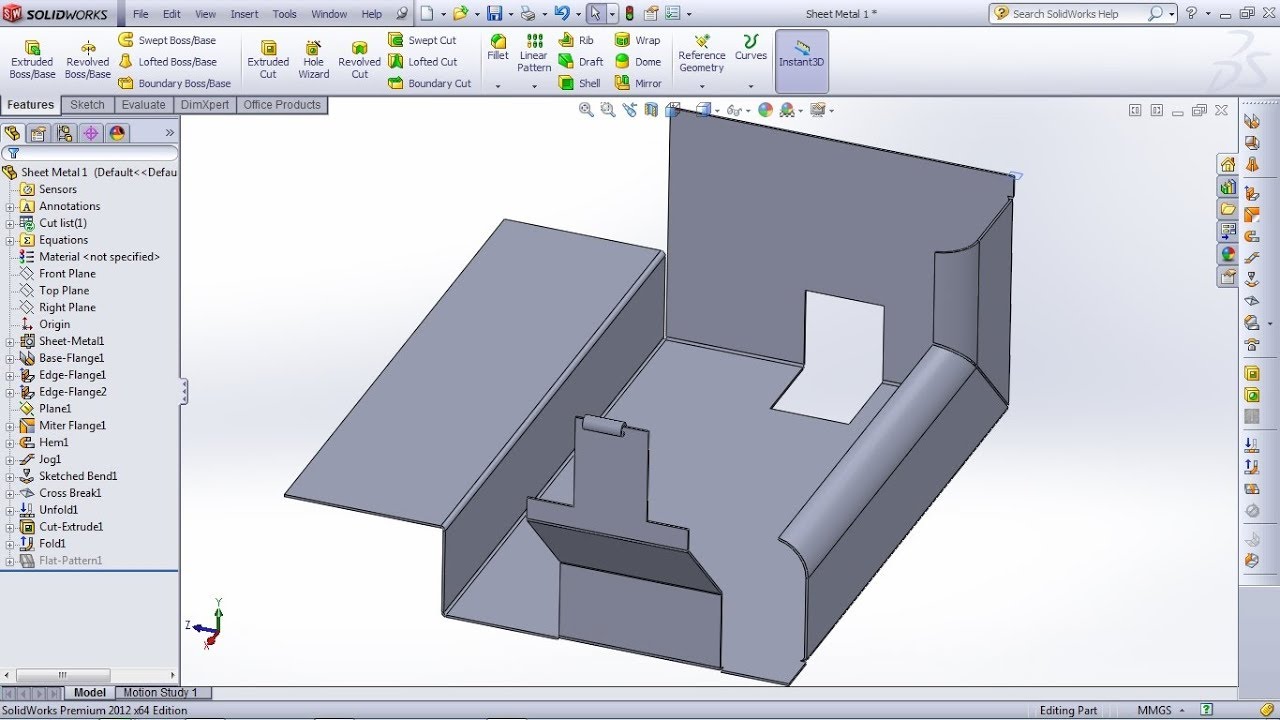

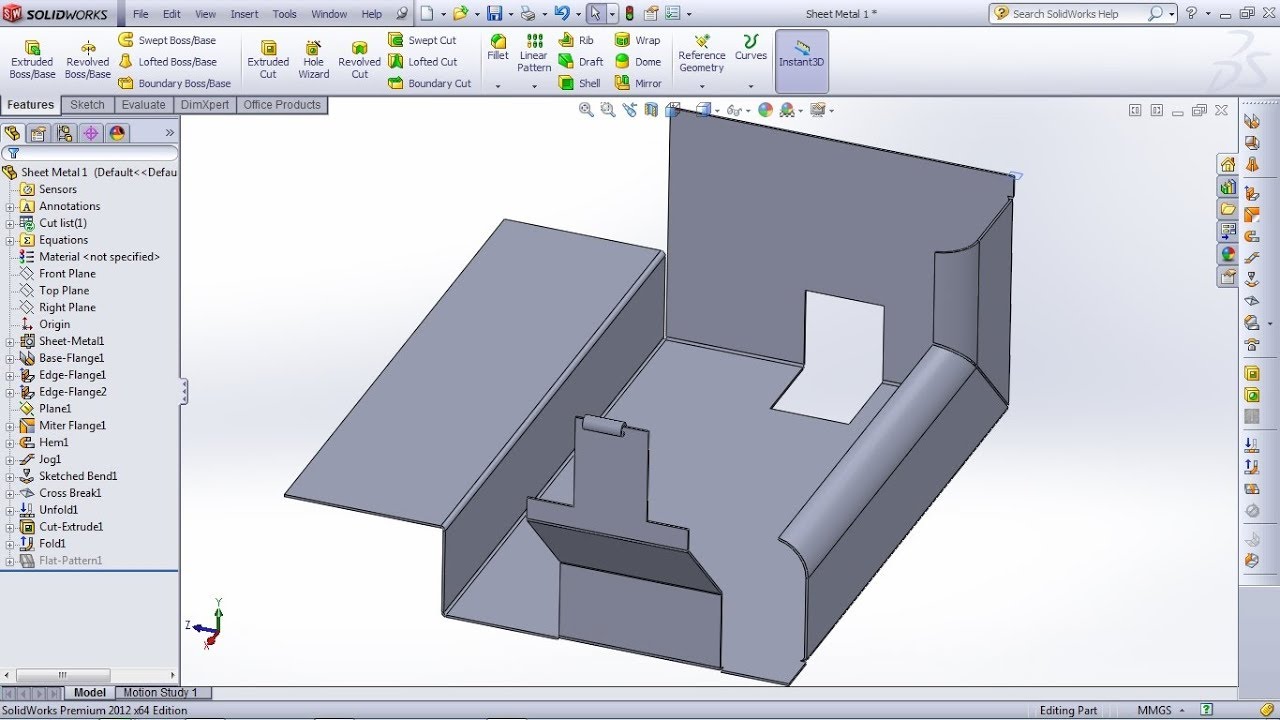

There are specific sheet metal features you can use to create sheet metal bodies quickly.

Solidworks fundamentals of sheet metal.

Forming tools are parts that act as dies that bend stretch or otherwise form sheet metal to create form features such as louvers lances flanges and ribs.

Sheet metal is the metal formed into thin and flat pieces which uses sheets of thickness less than 6 mm.

Using forming tools with sheet metal.

You can cut or bend into various shapes using sheet metal.

The greatest feature of sheet metal is that it s having ability to be formed and shaped by no of process.

However in some circumstances when the design requires certain types of geometry you can use non sheet metal feature tools then insert bends or convert the part to sheet metal.

Multibody sheet metal parts.

Solidworks 3d allows you to quickly create sheet metal part designs using a simple design process saving you time and development costs thanks to specific sheet metal features.

It is one of the main and basic forms of metal working.

Converting solid bodies to sheet metal.

We will focus on the flange method where a sheet metal part is created in the formed state using specialized sheet metal features.