When cleared the body is consumed by the convert to sheet metal feature.

Solidworks convert rolled part to sheet metal.

In the convert to sheet metal propertymanager you specify the fixed face and thickness of the sheet metal part the default bend radius and the edges or fillet faces on which to create bends.

Solidworks converting surfaces to solids multiple methods preparing a solidworks model for 3d printing.

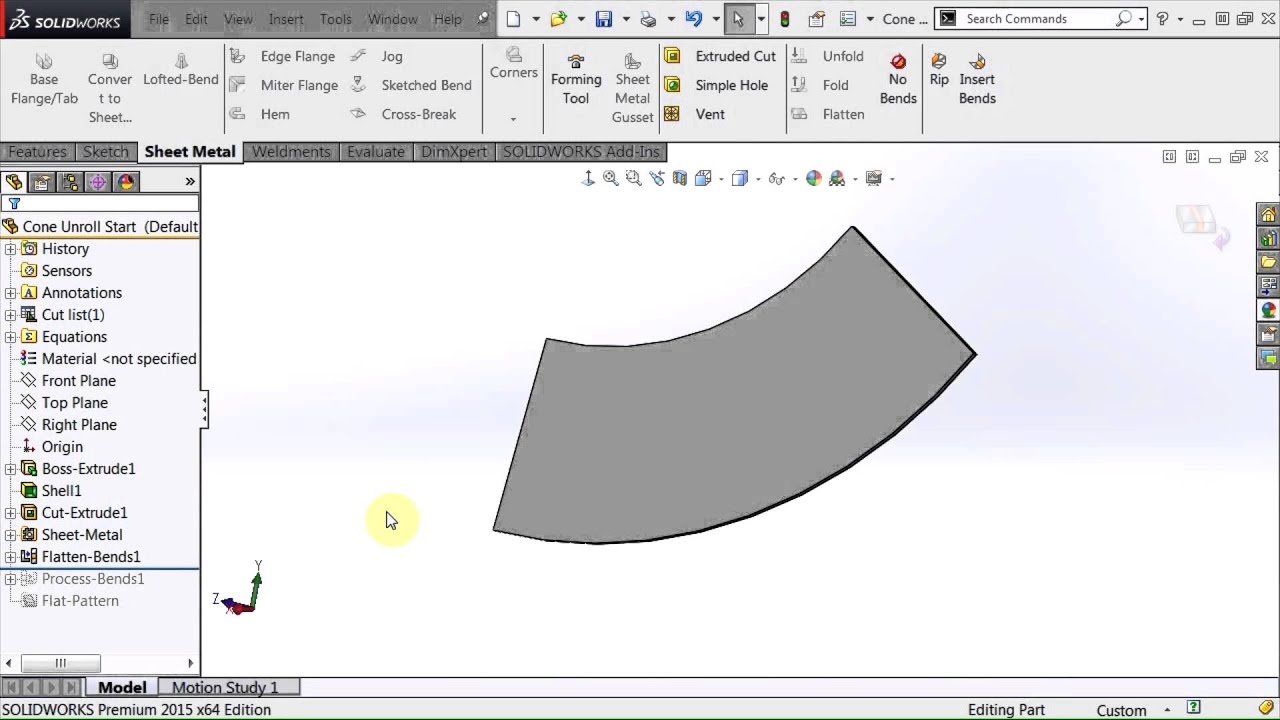

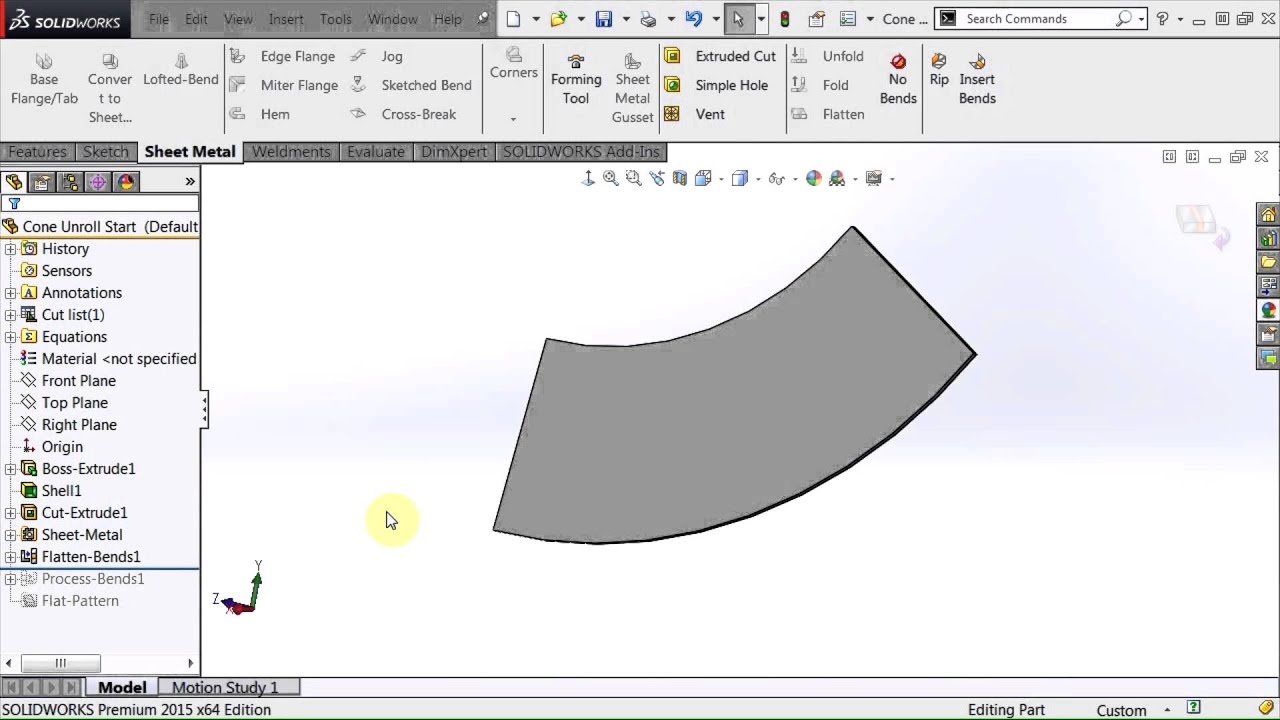

First phase in creating a rolled sheet metal component within solidworks once the sketches are complete it is time to use the sheet metal lofted bend tool.

Export model of car from 3ds max to solidworks.

How to import polygonal models in solidworks.

Select a face as the fixed face for the sheet metal part.

How to convert 3d part into sheet metal in solidworks.

Select keep body if you want to keep the solid body to use in another convert to sheet metal feature.

Under sheet metal parameters.

The software automatically selects the edges on which rips are applied.

This video shows the difference between creating a sheet metal part from scratch and converting a solid part to sheet metal.

For more information about solid.

This tutorial shows how to convert cylindrical hollow solid part to sheet metal cylinder.

If an edge already has a fillet applied the radius of the fillet is used as the bend radius for the new sheet metal part.

Pick the a face that will be fixed plane of the flattened sheet 4.

Solidworks convert to sheet metal cylinder.

This will create a lofted section from your two projected sketches.

Click convert to sheet metal 3.

Ive attached the file but i had to change th.

How to convert 3d wireframe into 3d model in solidworks.

Convert solid to surfacebodies.

If you don t have the sheet metal tab open right click in the area where the 1 arrow points then click sheet metal.

This curved plate has neither.

Second phase in creating a rolled sheet metal component within solidworks.