However in some circumstances when the design requires certain types of geometry you can use non sheet metal feature tools then insert bends or convert the part to sheet metal.

Solidworks bent round bar using sheet metal.

There may come a time when the product needs to be produced from round bar stock.

Set offset distance as 0 1in.

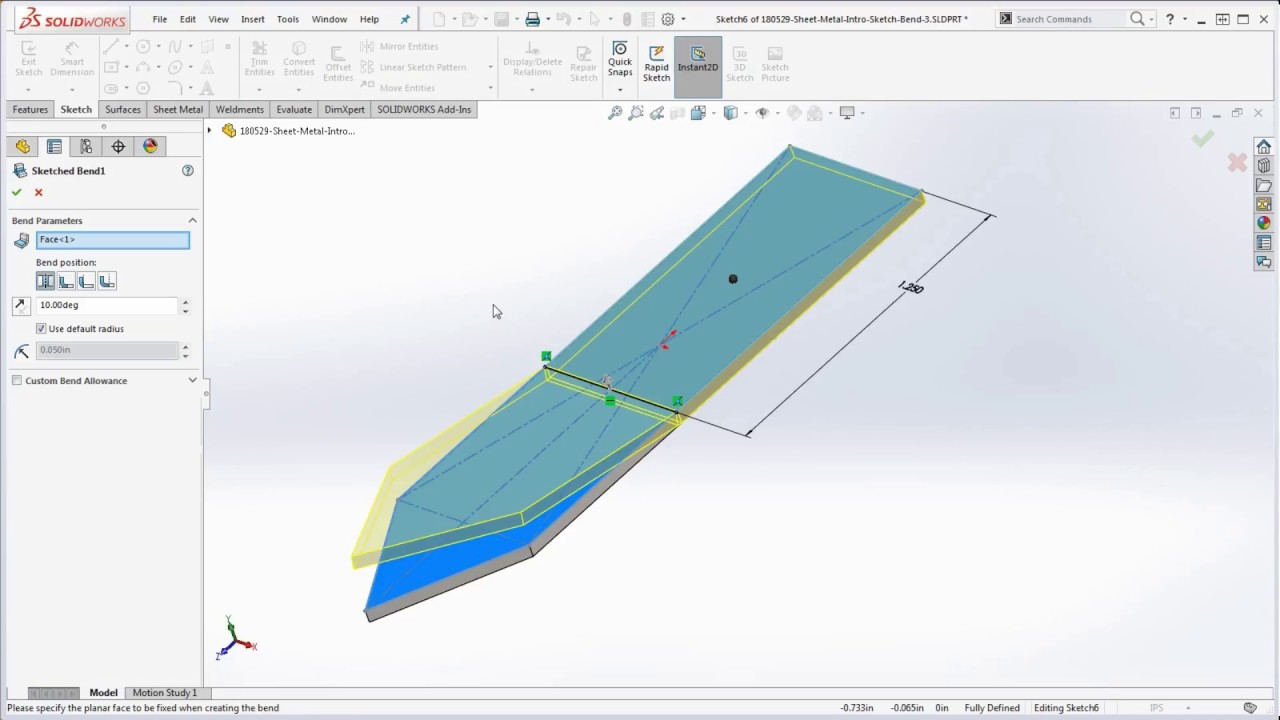

In the propertymanager under bend parameters.

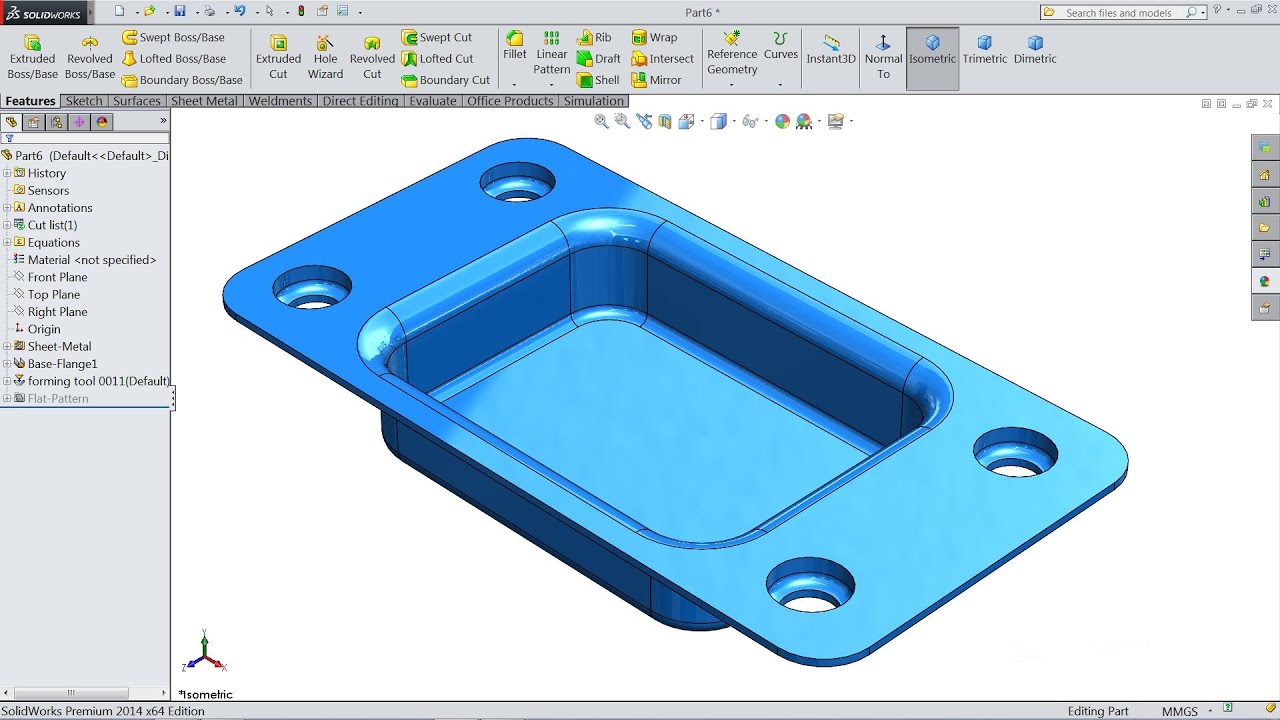

When creating a sheet metal part in solidworks one of the key features is the capability to flatten the model into a sheet so it can be manufactured.

Click a face or edge on the model for fixed face or edge.

The fixed face remains in place when the part is flattened.

The fixed face remains in place when the part is flattened.

It is important to keep in mind that there exists a central plane of metal near the center of thickness that remains unchanged no compression or stretching.

This allows the manufacturing entity to have a flat pattern drawing derived from the created part.

Click offset entities and click l sketch.

Dimension sketch with smart dimension as 1in x 1in.

Select the fixed face on the model.

In this tutorials you will learn how to utilize sheetmetal tool such insert bend and flaten.

No more than two sketch profiles are allowed.

There are some characteristics of lofted bends that are unique from a standard loft or sheet metal part and they are.

You might also like.

Use line sketch l shape.

The gaps in the profiles should be aligned for flat pattern accuracy.

The name of the face is displayed in the fixed face or edge box.

Use of guide curves is not supported.

When a piece of sheet metal is bent the inside radius material at the bend region is compressed while the outside radius material is stretched.

There are specific sheet metal features you can use to create sheet metal bodies quickly.

In the propertymanager under bend parameters.

Click front plane and click on sketch.

Click insert bends sheet metal toolbar or insert sheet metal bends.

Type the bend radius.