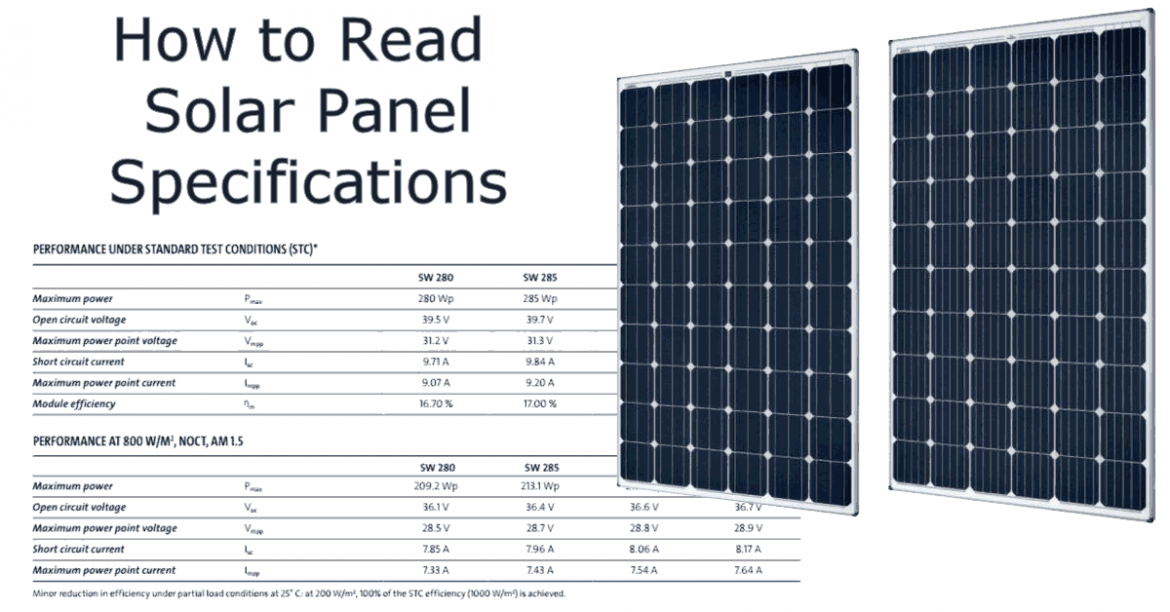

60 cell solar panels are typically 5 4 feet tall by about 3 25 feet wide and have a power output in standard test conditions of between 270 watts to 300 watts depending on the exact efficiency of the cells in them.

Solar cell panels square meter cost manufacturing.

Some people associate solar power with heat because heat is associated with lots of sunlight but if there s too much heat your solar panels may not work as effectively.

Solar panel manufacturing unit means solar panel assembly line which includes different kind of machines these machines combines and make an assembly unit.

The average solar panel payback period is 7 to 12 years and solar energy saves 600 to 2 000 per year on electricity costs.

The average cost to install solar panels is from 10 626 to 26 460 after tax credit for a 6kw to 12kw system to power an entire house.

The specific manufacturing process is as below.

Polysilicon is the key raw material used to make silicon wafers.

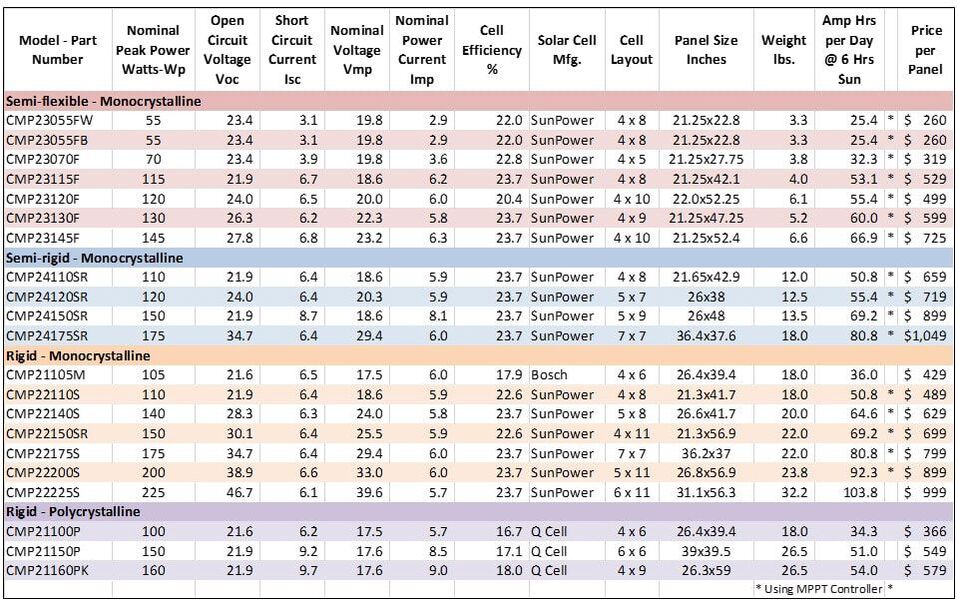

Solar panel efficiency is a measure of the amount of solar energy irradiation which falls on a panel surface and is converted into electricity due to the many recent advances in solar cell technology over the last 5 years average panel conversion efficiency has increased from 15 to 20.

In terms of power output it is best to separate solar panels into two categories.

The manufacturing process of crystalline silicon solar cells is as below diagram.

Polysilicon a major solar cell cost contributor.

Most of rec s solar pv systems are typically priced between 2 44 and 3 06 per watt which makes them a strong value in the market for home solar panels.

Average solar panel cost.

The most recent official data from the doe funded lawrence berkeley labs published in september 2019 found that the median cost of residential solar panels is 3 70 watt.

It is the developing mainstream of solar cells technology to improve conversion rate of solar cells and decrease cost.

The manufacturing technique for solar cells.

This material has been pegged as a major cost contributor to the overall pv cell manufacturing representing 30 or more of the overall cell cost.

While most solar panel manufacturers offer a ten year materials warranty rec provides a maximum of 20 year warranty against any defects in their solar panels.

It includes 1 automatic laminator 2 solar cell.

The total wafer cost represents more than 60 of the overall cell costs.

National data september 2020.

To produce the maximum amount of power per square foot a solar panel has to be well designed to handle temperature spectrum angle and amount of light.

This large jump in efficiency resulted in the power output of a standard size.