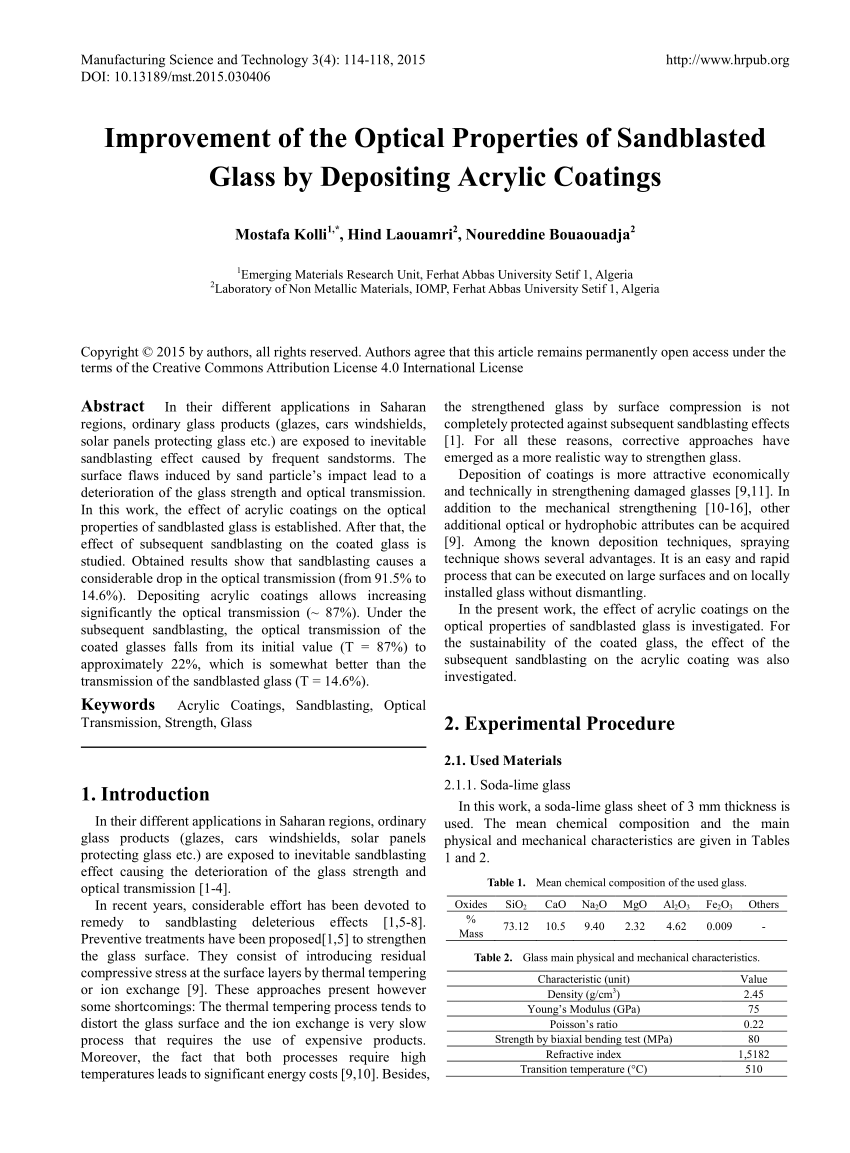

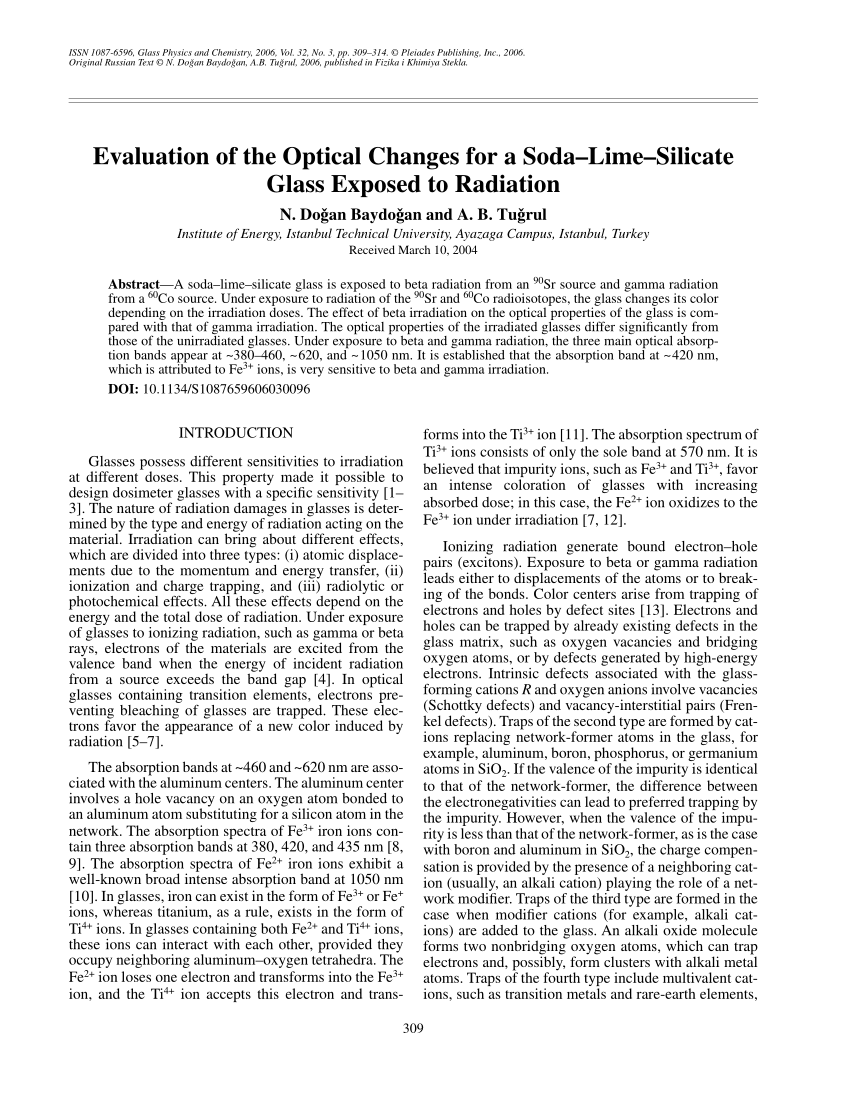

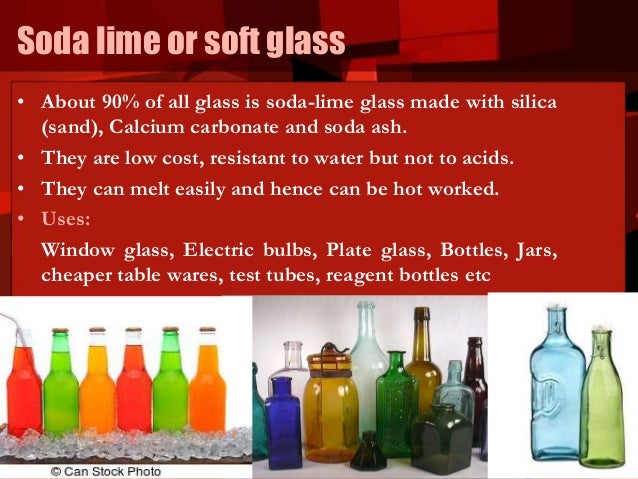

Soda lime glass is the most prevalent type of glass and is prepared by melting the raw materials such as soda lime silica alumina and small quantities of fining agents in a glass furnace at temperatures up to 1675 c.

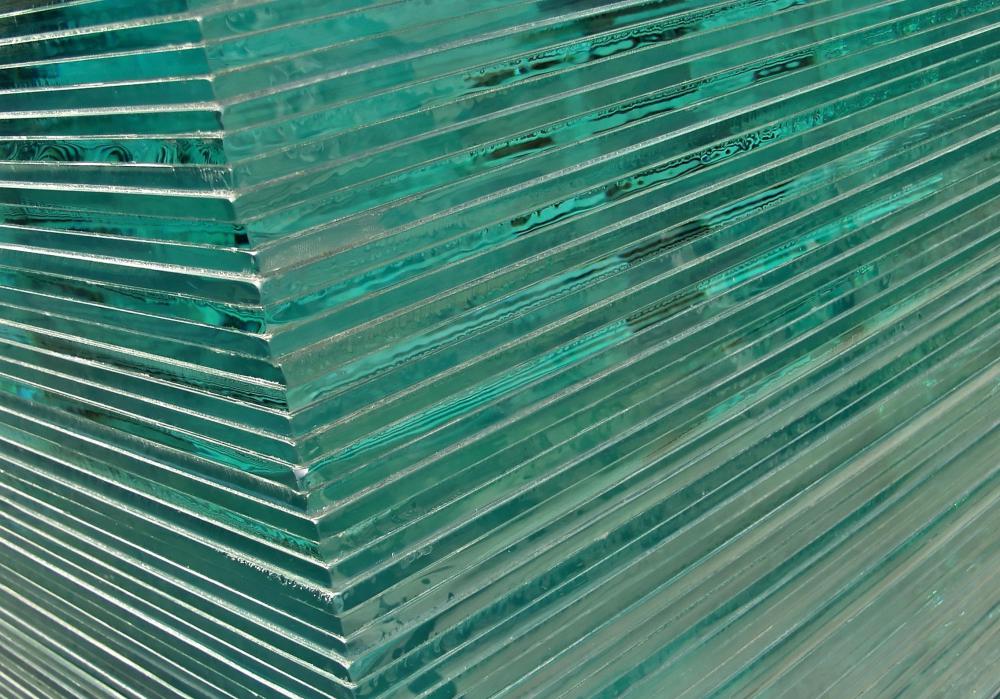

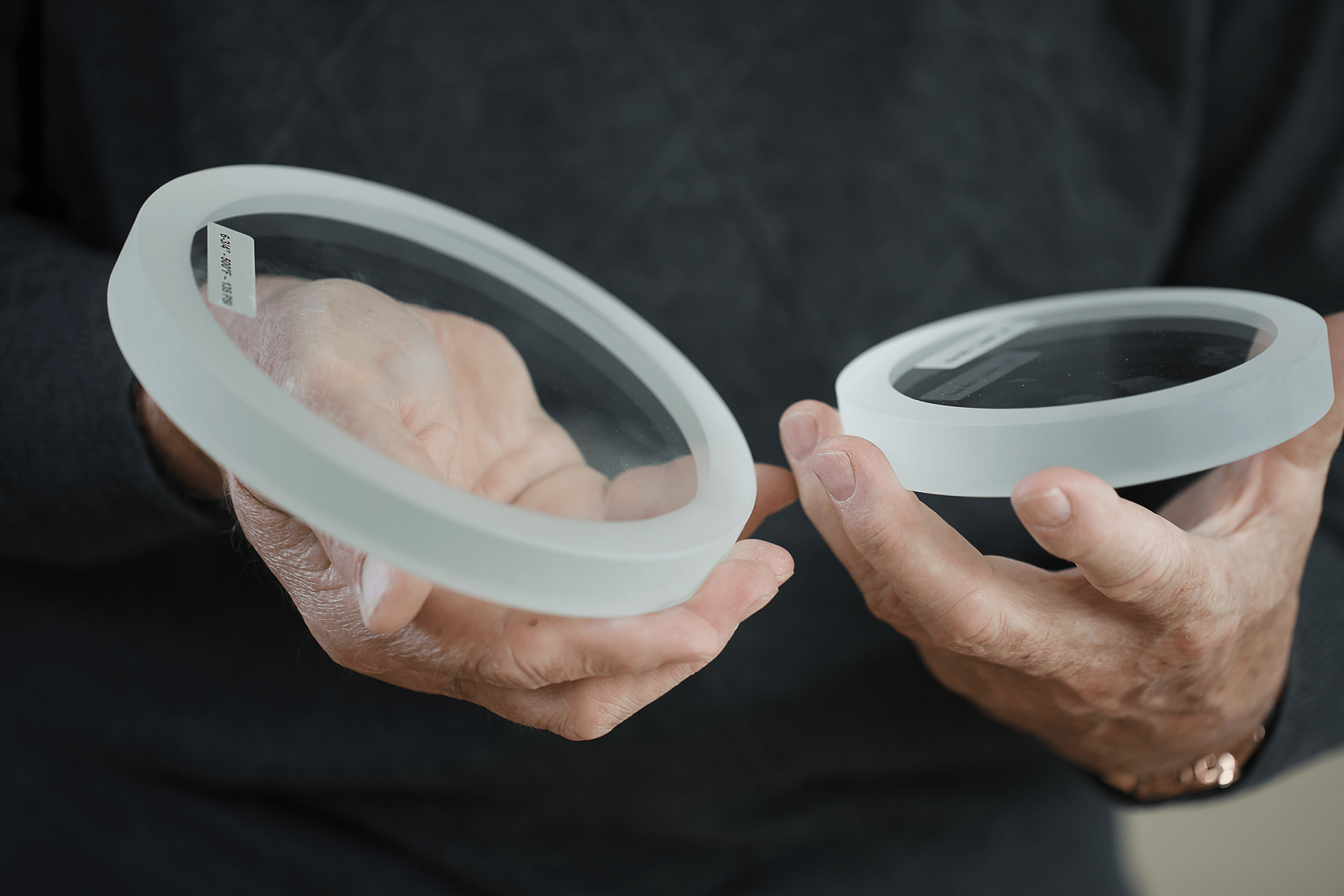

Soda lime glass sheets.

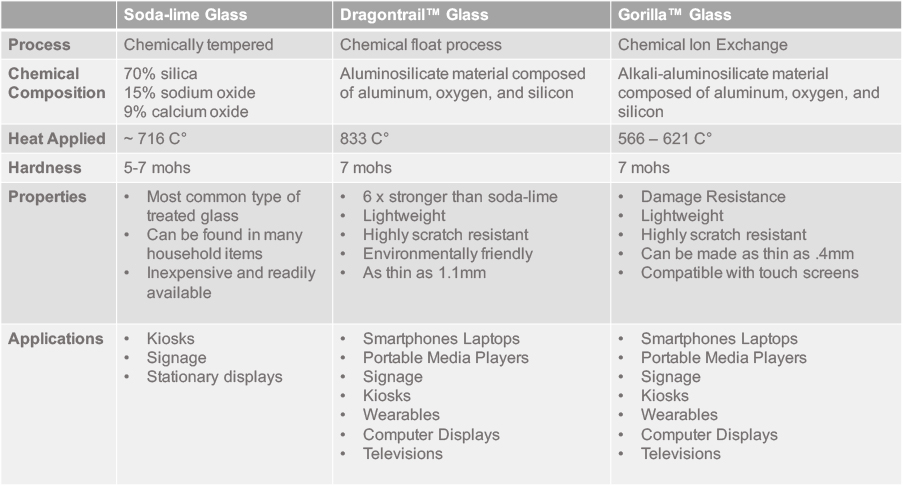

Composition alkali alkaline earth silicate glasses usually about 12 16 alkali na 2 o 8 16 alkaline earths cao mgo 0 2 al 2 o 3 and about 71 75 sio 2.

Abrasive type e and f silicon carbide download pdf.

Soda lime glass can be used in a wide range of applications.

This method gives the sheet uniform thickness and very flat surfaces.

Soda lime sheet glass is made by a floating molten glass on a bed of molten tin.

Abrasive type g l u and w sodium.

Soda lime glass having high heat insulating property the soda lime glass may be hereinafter simply referred to as a glass is required to be used as window glasses of vehicles such as automobiles.

Stock thicknesses range from 0 4 mm thick to 19 mm thick and the sheet sizes are typically 12 inch 14 inch 16 inch and 20 inch squares of each.

This method gives the sheet uniform thickness and very flat surfaces.

Our flint glass tubing has a wall thickness of 1mm to 1 2mm.

Crushed glass or glass bead dowload pdf.

The manufacturing process for soda lime glass consists in melting the raw materials which are the silica soda lime in the form of ca oh 2 dolomite camg co 3 2 which provides the magnesium oxide and aluminium oxide.

Flint glass is also known as soda lime glass.

Check up to five results to perform an action.

Abrasive type m or y plastic download pdf.

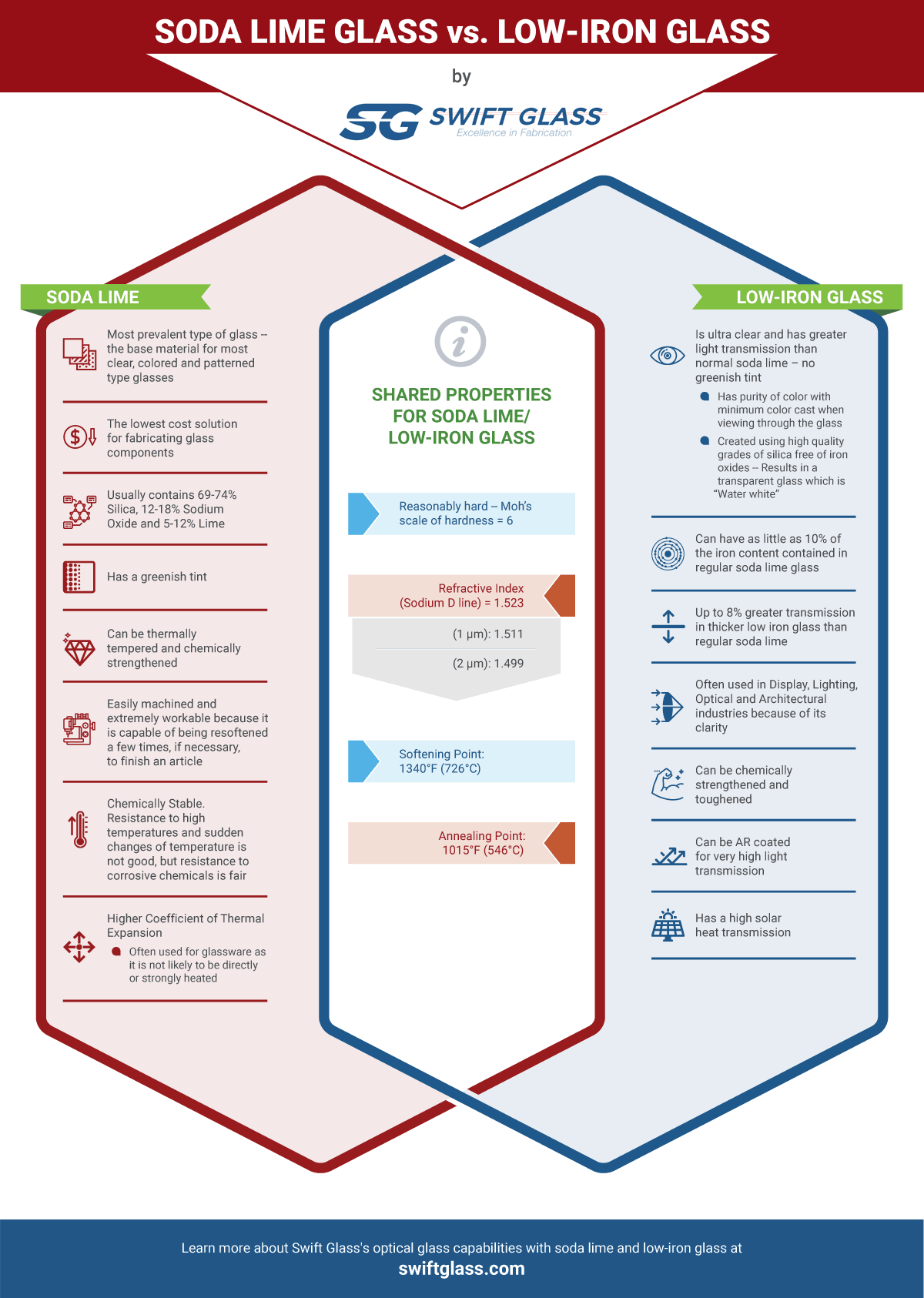

Soda lime is the base material for most clear colored and patterned glass types.

Section 4 first aid measures glass dust.

Trace amounts of the metals fe se ni cr and co are purposely added to some compositions to color the glass and trace amounts of pb is sometimes present as a contaminant.

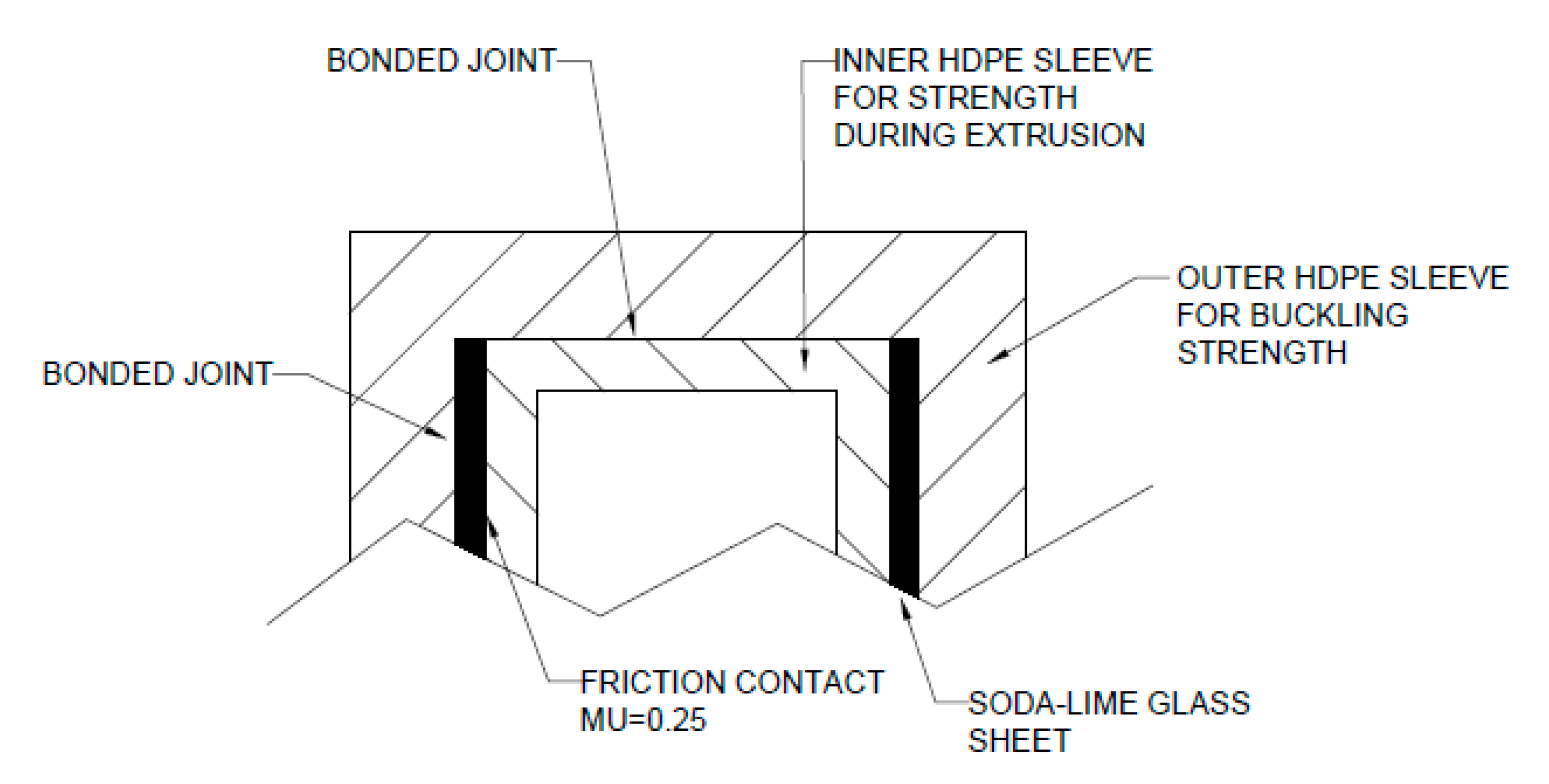

Soda lime glass soda lime glass is often referred to as float glass because it is formed by drawing glass over molten tin baths.

When the glass has low heat insulating property the temperature inside vehicles receiving solar radiation increases.

Pricing listed is per square foot based on stock sheet size.

The products listed in section 1 are based on typical soda lime silicate at glass.

Soda lime glass is the base material for most clear colored and patterned glass types.

Silicon dioxide sio 2 69 74.

Soda lime glass is prepared by melting the raw materials such as soda lime silica alumina and small quantities of fining agents in a glass furnace at temperatures lo cally up to 1675 c.

Soda lime sheet glass is made by floating molten glass on a bed of molten tin.

This assorted set of flint soda lime glass tubing includes 46 pieces total all.

Along with small quantities of fining agents e g sodium sulfate na 2 so 4 sodium chloride nacl etc in a glass furnace at temperatures locally up to 1675 c.

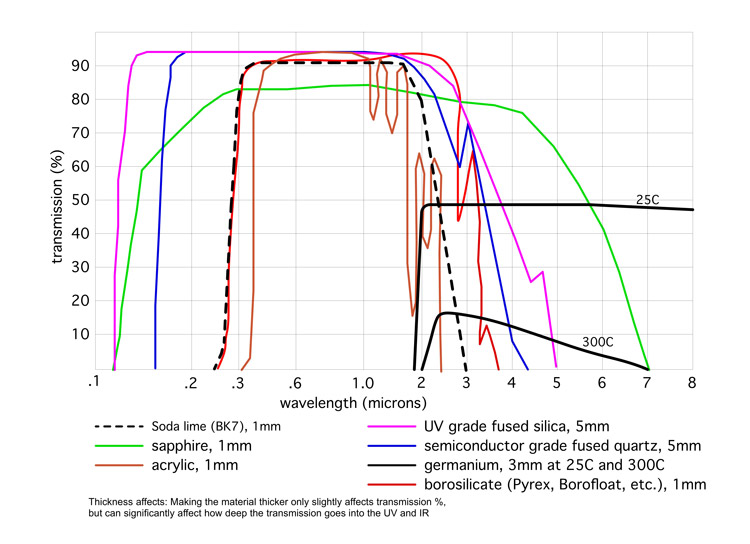

When compared to borosilicate glass it has a lower melting point chemical resistance and expansion rate.