These machines can also consolidate multiple steps into a single cycle virtually eliminating secondary finishing processes such as polishing annealing or welding.

Small plastic sheet hydroforming press.

Thick thinned in the bent areas along the circumference and wrapped into a rectangle with radiused corners.

Find your plastic press easily amongst the 102 products from the leading brands fagor on directindustry the industry specialist for your professional purchases.

Deep drawing is often more cost effective than spinning when the run quantity is very large and a high production rate is required.

To illustrate the types of small parts we form here are five examples of hydroformed parts made at our manufacturing facility in west lafayette ohio.

Hydroforming plastic aluminium.

Our tanks are formed from sheet stock typically 0 25 in.

From hobby to engineering architectural to special effects to educational plastruct is your one stop source for all your modeling needs.

From traditional hydraulic forming presses to servo electric presses and specialty forming equipment beckwood leverages decades of experience engineering and manufacturing forming equipment to exceed your operational demands.

Plastruct is the world s leading supplier of plastic scale model parts for every facet of miniature scale model building.

Beckwood forming presses are used by companies across the globe tackling some of the most challenging forming applications.

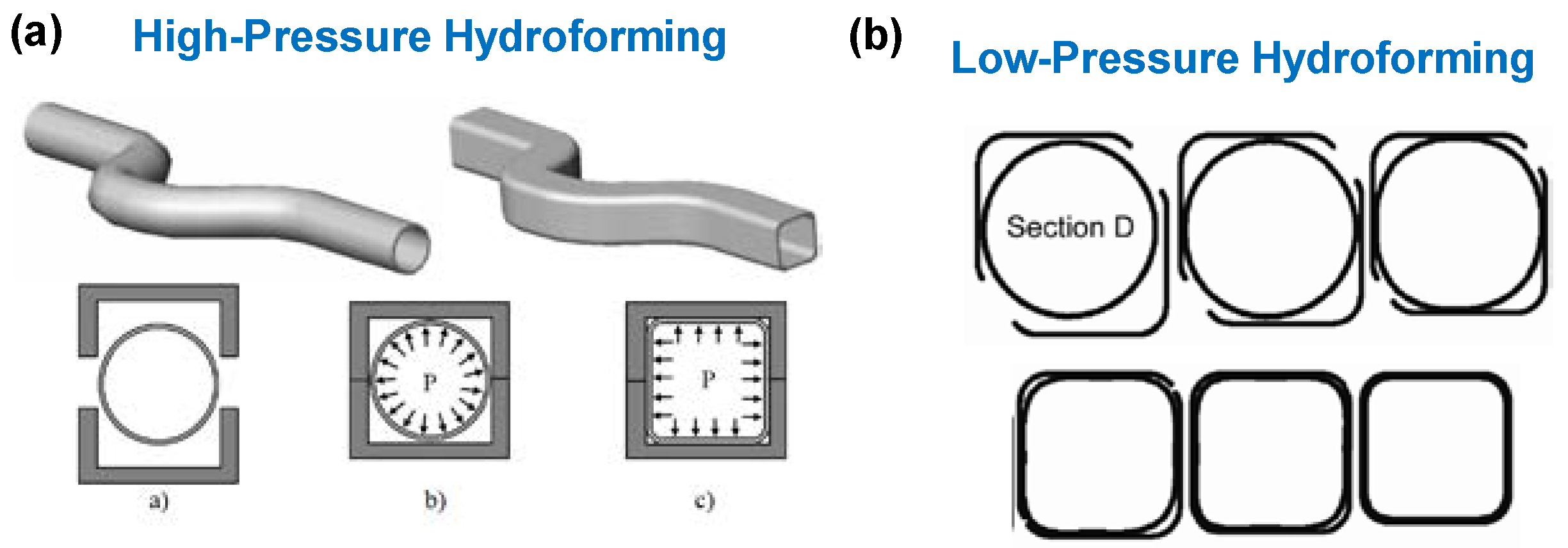

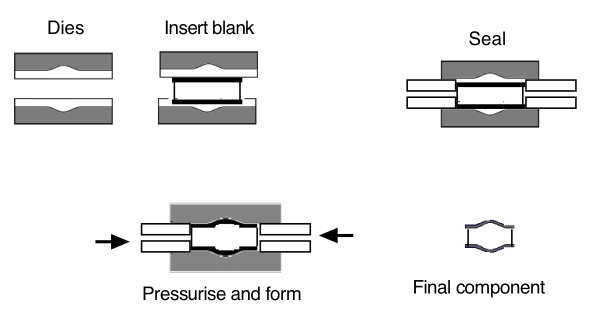

Hydroforming presses macrodyne hydroforming presses are designed for both high and low pressure complex hydroforming applications involving sheet or tubular based parts.

At jones metal products our hydroforming capabilities cover a broad range of product sizes shapes and specifications.

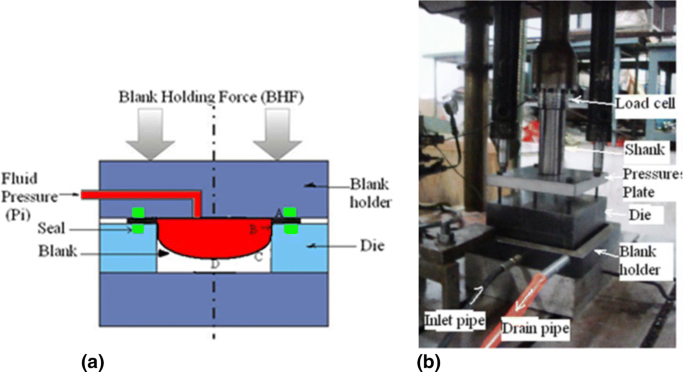

Sheet hydroforming presses can combine and or replace many different metal forming processes including press brakes traditional draw forming rubber pad forming progressive die forming and more.

I am forming plastic not metal but i am applying metal bending principles to my application after a few years of iteration we have developed an accurate flat pattern method for our tank bending operations.

Our hydroforming presses are used for the production of automotive components tank manufacturing plumbing and a wide variety of industrial product manufacturing applications.

Hydroform usa is equipped with three high pressure hydroform presses that can form large metal components up to 15 inches in depth.

Hydroforming is suited for parts that have contoured shapes like doors structural components or fuel tank details.

The triform 16 10 7dd deep draw sheet hydroforming press offers a 16 inch forming space and an incredibly capable 10 000 psi of pressure.

Hydroforming may be the desired forming technique when minimal material thinning is required.