In general such products have good punching characteristics and are used in a variety of applications including small rotors stators and small power transformers.

Silicon steel sheets are used to reduce the.

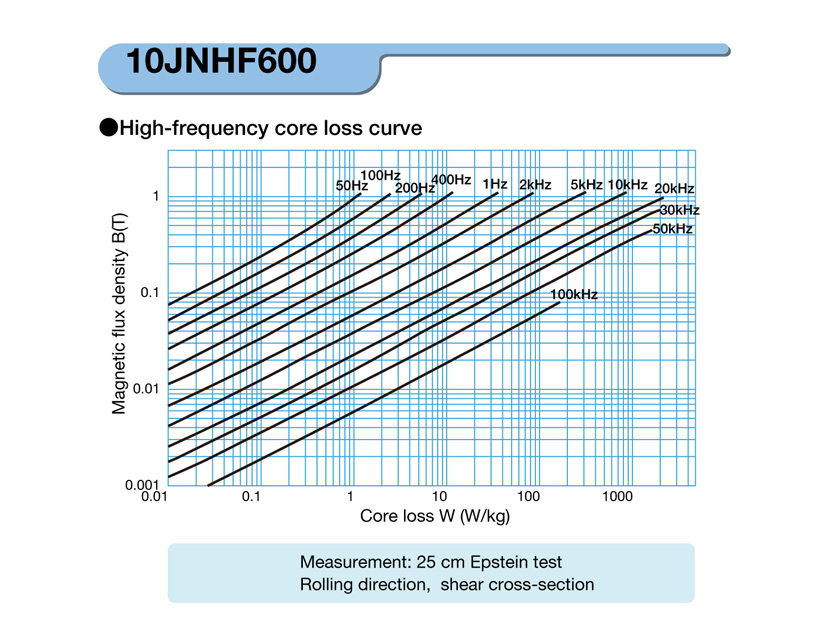

In order to reduce these eddy currents about 4 to 5 of silica impurity is added so that the conductivity of steel decreases.

The right welding process can help improve results with.

Core losses windage and friction losses stator losses rotor losses and stray load losses.

This not only reduces the eddy current loss lowers the temperature rise but also saves the material of silicon steel sheet.

But in fact when making silicon steel sheet iron core.

Reheating is commonly used to soften steel before hot rolling into ultra thin silicon steel sheets referred to as electromagnetic steel.

Until the late 1930s thin laminations of hot rolled silicon iron often referred to as silicon steel were used almost exclusively in transformer cores.

When low carbon steel is alloyed with small quantities of silicon the added volume resistivity helps to reduce eddy current losses in the core.

High heating rates are required to reduce the time spent in the reheating furnace to increase the efficiency of producing ultra thin electromagnetic steel sheets and decrease fuel consumption.

If pure steel is used as a magnetic core in a transformer it acts as a good conductor and whenever a time varying flux passes through core circulating current are produced and are known as eddy currents.

Sheet by single stage shear based processing.

Silicon iron has a relatively high permeability and the increased resistivity due to the silicon helped reduce the eddy losses.

Be divided into five major categories.

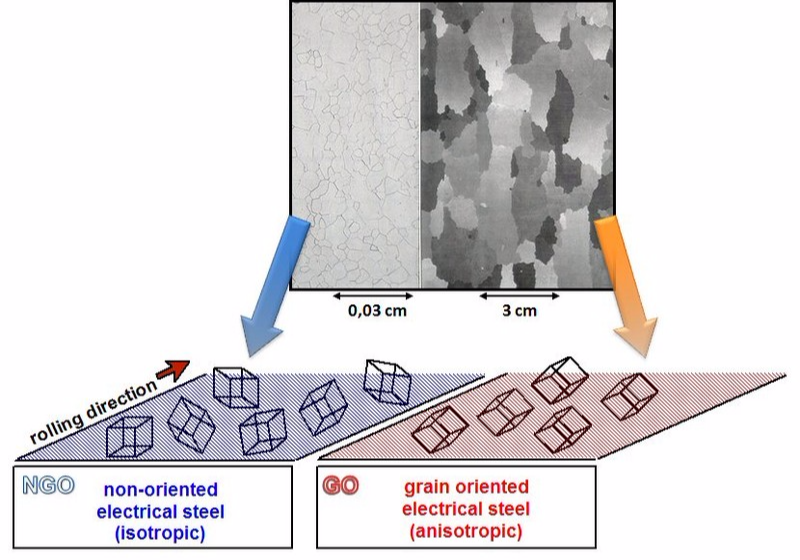

Since hot rolled silicon iron has approximately the same magnetic properties in all directions in the plane of the laminations a simple 90 butt overlap corner joint could be used for stacked cores.

Process enables production of steel alloy sheet for use in electric motor cores energy losses in electric motors can.

Sheet metal comes in a range of thicknesses and people may have different definitions of what they consider sheet metal to be depending on their application.

Use pulsed mig welding.

Goss the early inventor of the cold rolled grain oriented silicon steel or crgo steel manufacturing process in 1933 gave the idea in his own words i have experimental evidence which leads me to believe that there is an apparent relation between the grain size and ductility of a specimen and its magnetic properties.

Silicon steels are probably of the most use to designers of motion control products where the additional cost is justified by the increased performance.

In theory if the thickness of the silicon steel sheet is thinner to reduce the eddy current the narrower the spliced strips the better the effect.